How Diamond Cuts are made?

Most of the people that bought diamonds will tell you to look at 4Cs which are Carat Weight, Cut, Clarity, and Color. But something else can affect the price for even 30%. The shape is important more than some other features. It doesn’t have to be large to look like it is large on your finger that can be done through proper shaping. The most popular and the most expensive is round brilliant.

A lot of time and effort is put into making a diamond ring. It starts with a big rock that goes through a rough process to become something beautiful. There are a lot of shapes you can choose from, everything depends on the taste. Also, the price will be different for each cut. Before you buy it in the first store you visit, do some research because maybe they don’t have every type.

If you want to learn more about diamonds cuts and shapes, read here: https://diamore.be/diamond-shapes-cuts/

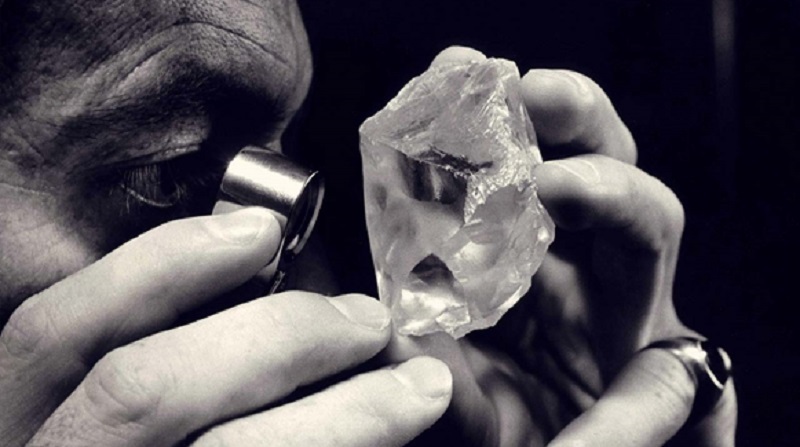

Diamonds before Cutting

It is obvious that diamonds don’t come from the ground looking like at the store. Before cutting the diamond has jagged edges, and it is a very rough milky stone. The cutter’s job is to make it into something beautiful. There are five steps every cutter follows. The first thing is the planning which is very important because they must analyze the rock and figure out a way to minimize waste. The goal is not to drop the value of the rock.

Cleaving and Sawing

The diamond is the weakest along the tetrahedral plane, and the cutter must cleave there before cutting. A cement or was mold is holding the diamond in place as the worker carves sharp incision along the plane. They cut it into two pieces by placing a steel blade in the incision and striking it. You have to use some force to do this, it won’t make any damage to it.

It can happen that cleaving isn’t enough because there is no weak point, so you have to use other methods. Sawing is the second method they use, and this is done with a phosphor-bronze blade that rotates at about 15k rpm. There is advanced technology now where lasers are used to do the cutting, but it takes much longer to finish the process. At this step, the cutter needs to decide with part will be the flat top of the diamond, and which will be the outside rim also called girdle.

Cutting or Bruiting

The most important part besides planning is making the correct shape. These techniques are the same thing, but the bruiting is done by hand and cutting is done by the machine. An interesting thing is that diamonds are used to cut diamonds if the cutter shapes them by hand. They rely on their hardness. The instrument used looks like a stick with a tip that carries the diamond.

Only one corner is exposed at the top of the stick, so it will be sharp. They use two sticks in the process, one for the diamond being processed. By rubbing the parts, they make the desired shape. In most cases, they will use the mechanical process where they place it in a lathe and rub it against another diamond to make the rough finish. Click here to read more.

Polishing

There are different ways to get to polishing, but once you are there it is too late to go back and have a different shape. Workers use a spinning wheel to make the surface smooth. You should also learn about cleaning methods for your jewelry. After the polishing, they have to go through inspection to check if everything is done as planned.

Which One Looks the Biggest?

Many people want the right answer to which diamond will look the biggest on their hand, so they won’t have to spend life savings on it. It is usually determined by how many carats it has, but cutters know how to make them appear large. Having good spread is a reference to a stone that looks bigger than its carat size.

The first sign of good spread is when the cut grade is Excellent. The shape that looks the biggest is round because they are great at reflecting light. When you understand how to cutting process is done, you will know what questions to ask the seller. It will be easier to make the decision.